Kennametal Is The World’s Largest Supplier of Genuine Stellite 6B Products

Kennametal’s Stellite 6B (UNS R30016, AMS 5894) is a wrought material with enhanced physical & material properties. The forged microstructure gives Stellite 6B superior toughness and weldability, superior abrasive & erosive wear properties and superior corrosion resistance compared to a cast or welded Stellite 6.

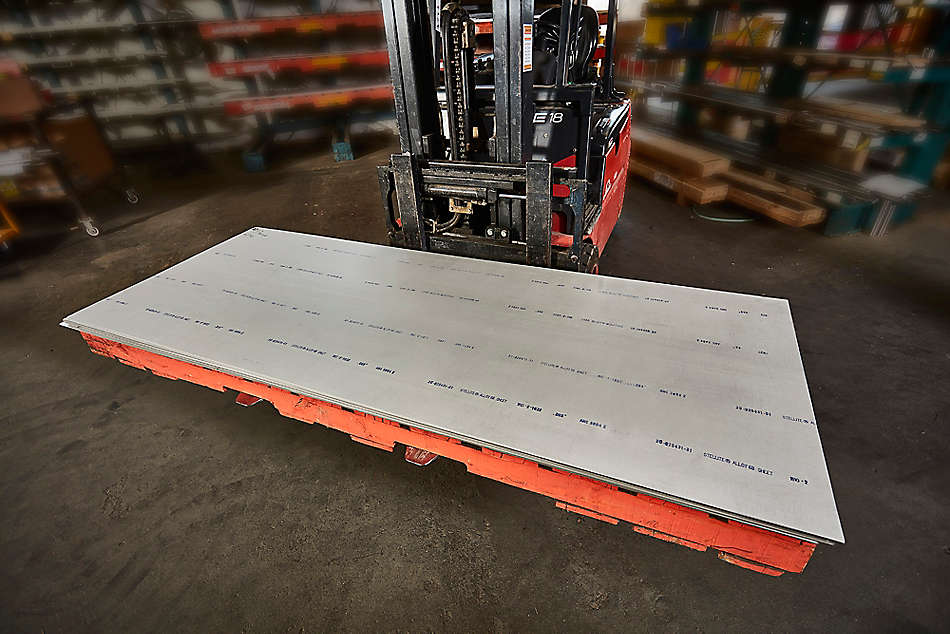

With its excellent wear characteristics, hot hardness, good corrosion resistance and superior mechanical properties, Stellite 6B has been the material of choice in some of the most demanding wear applications. These applications encompass aerospace bearings, steam turbine erosion shields, fan blades, steam turbines, wear plates, tunnel boring seals, gears, sleeves & bushings, drilling and exploration tooling.