High Temperature Strength, Wear & Corrosion Performance

The cobalt-based Stellite alloys are our most well-known and successful alloys, with the best “all-around” properties. They combine excellent mechanical wear resistance, especially at high temperatures, with very good corrosion resistance.

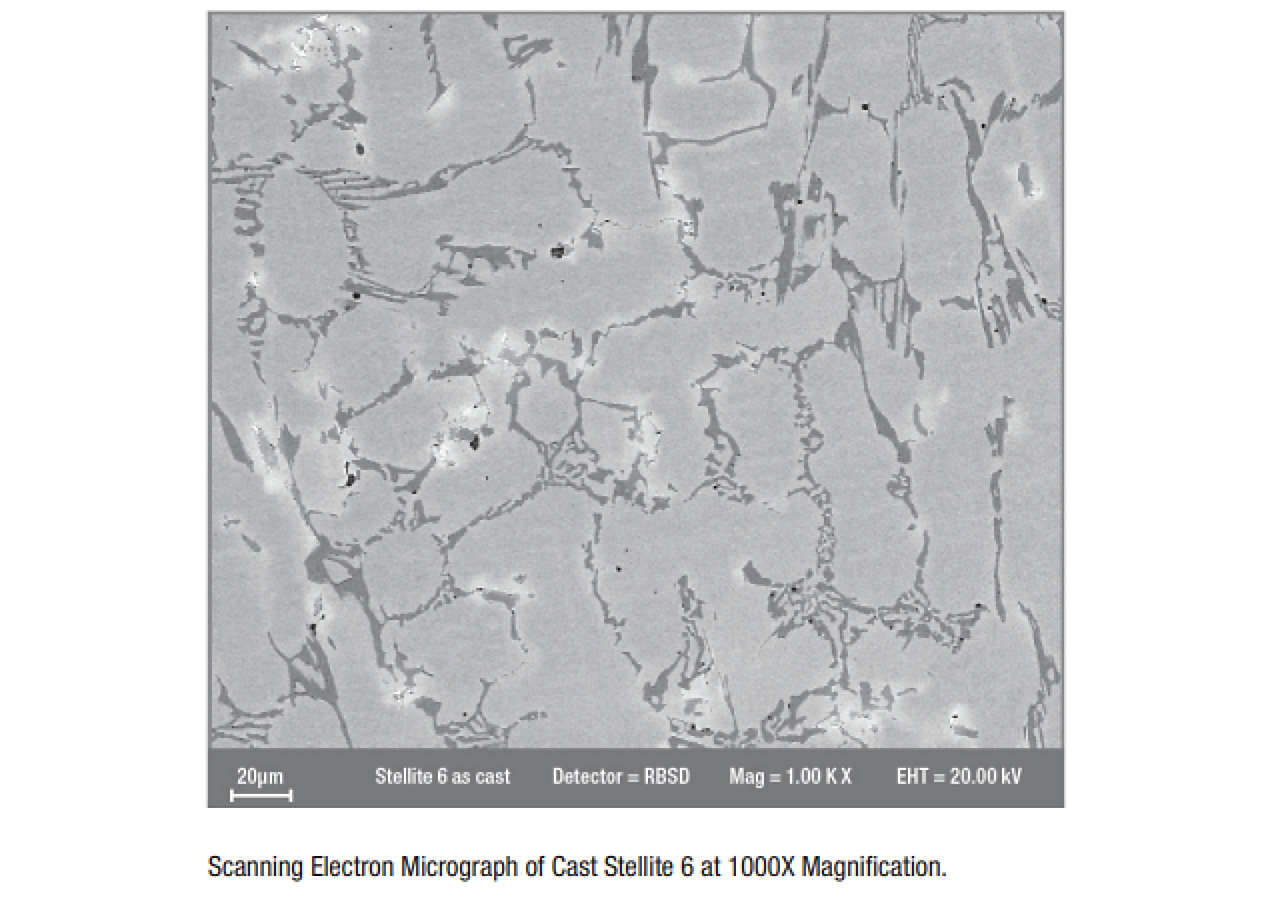

The Stellite alloys are cobalt based with additions of Cr, C, W and/or Mo. They are generally resistant to cavitation, corrosion, erosion, abrasion and galling. The lower carbon Stellite alloys are generally recommended for cavitation, sliding wear or moderate galling. The higher carbon alloys are usually selected for abrasion, severe galling or low-angle erosion.

The Stellite alloys retain their properties at high temperatures where they also have excellent oxidation resistance. They can be finished to exceptional levels of surface finish with a low coefficient of friction to give good sliding wear.