Nominal Composition (Mass %) and Physical Properties

| Ni | Cr | Mo | C | Nb+Ta | Fe | Others | Hardness | Density | Melting Range |

| Base | 21.5 | 9 | 0.1 max | 3.7 | 5 max | Si, Mn, Al, Ti | 25 HRC max | 8.42 g/cm3 0.304 lb/in3 | 1290-1350ºC 2354-2462ºF |

| Ni | Cr | Mo | C | Nb+Ta | Fe | Others | Hardness | Density | Melting Range |

| Base | 21.5 | 9 | 0.1 max | 3.7 | 5 max | Si, Mn, Al, Ti | 25 HRC max | 8.42 g/cm3 0.304 lb/in3 | 1290-1350ºC 2354-2462ºF |

Nistelle nickel-based alloys are designed primarily for high corrosion resistance. They have excellent high-temperature strength, resistance to oxidizing and/or reducing acids (depending on the grade) and are readily machinable.

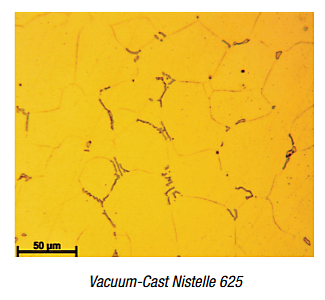

Nistelle 625 is a nickel-chromium-molybdenum alloy with an addition of niobium that acts with the molybdenum to stiffen the alloy’s matrix, thereby providing high strength without a strengthening heat treatment. The alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. It has excellent high-temperature oxidation and corrosion properties. Nistelle 625 is readily manufactured and fabricated by common industrial practices and has excellent weld qualities.

Nistelle 625 has been widely used in a range of high-temperature aerospace, chemical process, and power industry applications. As a low-temperature corrosion-resistant material, it has been used in the chemical industry, marine industry and in pollution-control equipment. It is widely specified for use in seawater and contaminated seawater environments.

| SPECIFICATION | PRODUCT FORM |

| AWS 5.14 ASTM A494 CW6MC UNS N26625 | Powder, Casting |

| AMS 5401 | Casting (Vacuum) |

| AMS 5402 | Casting (Air Melt) |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?