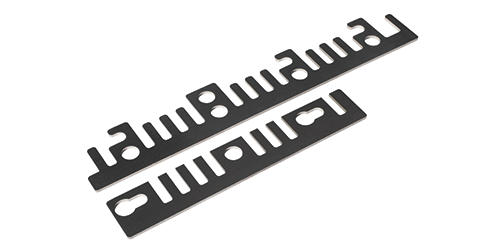

Stellite 6K – Cutting and Scraping Solutions for Severe Environments

Kennametal’s Stellite 6K is a hot-rolled material designed for industrial cutting and scraping applications. The carbon content of Stellite 6K is higher than Stellite 6B allowing for a higher hardness and better edge retention.

Stellite 6K is designed to hold a sharp edge in high-temperature, corrosive, and severe service environments. Stellite 6K knives, scrapers and slitters are found in a wide range of production equipment where edge-holding, quality of cut and resistance to corrosion are critical.

Stellite 6K is available in thicknesses ranging from 0.045" to 0.375“ and can be custom-rolled to your specification. Additionally, Kennametal Stellite can fabricate and finish Stellite 6K to print.