Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | C | Fe | Others | Hardness | Density | Melting Range |

| Base | 27 | 14 | 3.3 | <3 | Ni, Si, Mo, Mn | 52-60 HRC 570-760 HV | 8.66 g/cm3 0.313 lb/in3 | 1200-1335ºC 2192-2435ºF |

| Co | Cr | W | C | Fe | Others | Hardness | Density | Melting Range |

| Base | 27 | 14 | 3.3 | <3 | Ni, Si, Mo, Mn | 52-60 HRC 570-760 HV | 8.66 g/cm3 0.313 lb/in3 | 1200-1335ºC 2192-2435ºF |

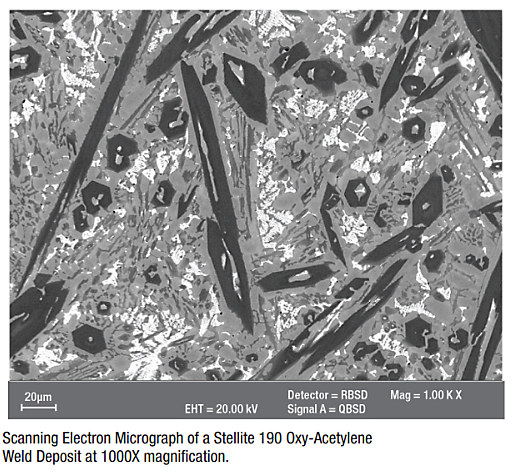

Stellite 190 is a highly abrasion-resistant alloy, primarily used for the hardfacing of bearing journals in tricone rotary rock bits used in the oil and gas industry. Tricone bits operate in hot and extremely abrasive downhole conditions. Due to the high proportion of carbides, which provide the abrasion resistance, care must be taken to minimize cooling stresses incurred during hardfacing and to avoid service conditions which involve severe mechanical or thermal shock.

Stellite 190 can only be finished by grinding.

| SPECIFICATION | PRODUCT FORM |

| UNS R30014 | Rod, Powder |

| AWS A5.21 / ASME BPVC IIC SFA 5.21 ERCoCr-G | Rod |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?