Nominal Composition (Mass %) and Physical Properties

| Co | Cr | W | C | Others | Hardness | Density | Melting Range |

| Base | 27-32 | 7.5-9.5 | 1.4-2.0 | Ni, Fe, Si, Mn | 45-51 HRC 435-590 HV | 8.53 g/cm3 0.308 lb/in3 | 1225-1280ºC 2240-2335ºF |

| Co | Cr | W | C | Others | Hardness | Density | Melting Range |

| Base | 27-32 | 7.5-9.5 | 1.4-2.0 | Ni, Fe, Si, Mn | 45-51 HRC 435-590 HV | 8.53 g/cm3 0.308 lb/in3 | 1225-1280ºC 2240-2335ºF |

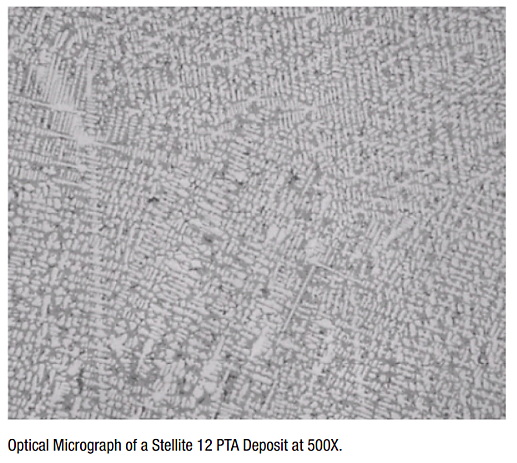

Stellite cobalt-based alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a CoCr alloy matrix.

Stellite 12 could be considered an intermediate alloy between Stellite 6 and Stellite 1. It contains a higher fraction of hard, brittle carbides than Stellite 6, and has increased resistance to low-angle erosion, abrasion, and severe sliding wear whilst retaining reasonable impact and cavitation resistance. Stellite 12 is often used self-mated or running against Stellite 6 or Stellite 1. The higher tungsten content provides better high-temperature properties compared to Stellite 6, and it can be used at temperatures up to about 700 ̊C.

Stellite 12 is typically used for cutting tools that need to withstand abrasion, heat, and corrosion. Examples include industrial knives for cutting carpets, plastics, paper and synthetic fibres; and saw tips in the timber industry. It is also used for control plates in the beverage industry, pump vanes, bearing bushes and narrowneck glass mold plungers; and for hardfacing of engine valves, pinch rollers in the metal-processing industries and rotor blade edges.

Stellite 12 can be supplied to the following specifications:

| SPECIFICATION | PRODUCT FORM |

| UNS R30012 | Rod, Castings |

| UNS W73012 | Electrode |

| UNS W73042 | Wire |

| SPECIFICATION | PRODUCT FORM |

| AWS A5.21 / ASME BPVC IIC SF A 5.21 ERCoCr-B | Rod |

| AWS A5.21 / ASME BPVC IIC SF A 5.21 ERCCoCr-B | Wire |

| AWS A5.13 / ASME BPVC IIC SF A 5.13 ECoCr-B | Electrode |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?