Nominal Composition (Mass %) and Physical Properties

| Co | Cr | Mo | C | Si | Others | Hardness | Density | Melting Range |

| Base | 17.5 | 28.5 | <0.08 | 3.4 | Ni, Fe | 54-62 HRC | 8.6 g/cm3 0.312 lb/in3 | 1288-1352ºC 2350-2465ºF |

| Co | Cr | Mo | C | Si | Others | Hardness | Density | Melting Range |

| Base | 17.5 | 28.5 | <0.08 | 3.4 | Ni, Fe | 54-62 HRC | 8.6 g/cm3 0.312 lb/in3 | 1288-1352ºC 2350-2465ºF |

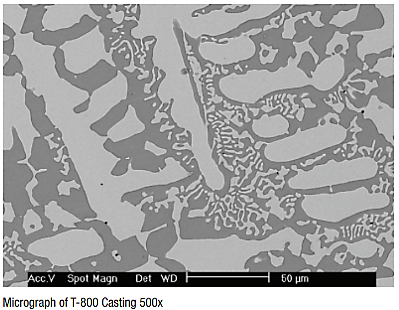

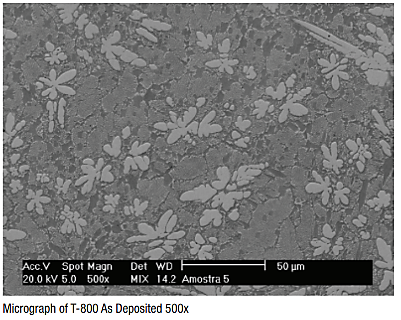

Tribaloy cobalt-based alloys consist of a hard, intermetallic (Laves) phase dispersed in a softer matrix of eutectic or solid solution. They exhibit outstanding resistance to wear and galling, high corrosion resistance and are particularly suitable where lubrication is a problem. Wear resistance of Tribaloy alloys is highly dependent on the volume percentage of the Laves phase.

Tribaloy T-800 alloy contains hard intermetallic phases of Mo and Si which give the alloy excellent wear properties over a wide temperature range. T-800 was designed to resist high-temperature wear and abrasion and has exceptional oxidation and corrosion resistance due to its high chromium content. T-800 is harder and more resistant to abrasive wear, corrosion, and oxidation than Tribaloy T-400. T-800 exhibits outstanding resistance to galling and is particularly suitable where lubrication is a problem.

Tribaloy T-800 has been used in a wide range of applications, most notably as a wear surface in aircraft engines. Other applications include galvanizing roll bushings, cams, retainer rings, diesel piston rings, mechanical seals, bearing seats, valve trim and pump components.

Areas of application where Tribaloy alloys are used:

| SPECIFICATION | PRODUCT FORM |

| B50TF193 | Solid Weld Rod |

| B50TF190 | Powder |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?