Nominal Composition (Mass %) and Physical Properties

| Ni | Cr | Mo | Fe | W | Co | Others | Hardness | Density | Melting Range |

| Base | 16 | 16 | 5 | 4 | <2.5 | Mn, V, Cu | 85-98 HRB | 8.89 g/cm3 0.321 lb/in3 | 1270-1305ºC 2318-2381ºF |

| Ni | Cr | Mo | Fe | W | Co | Others | Hardness | Density | Melting Range |

| Base | 16 | 16 | 5 | 4 | <2.5 | Mn, V, Cu | 85-98 HRB | 8.89 g/cm3 0.321 lb/in3 | 1270-1305ºC 2318-2381ºF |

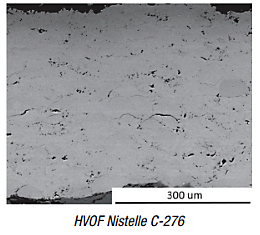

Nistelle nickel-based alloys are designed primarily for high corrosion resistance. They have excellent high-temperature strength, resistance to oxidizing and/or reducing acids (depending on the grade) and are readily machinable.

Nistelle C-276 is a nickel-chromium-molybdenum alloy with a long history of performance in corrosive applications. It was the first low C and Si alloy variation of the original Ni-Cr-Mo Nistelle C alloy. It is ductile, easy to weld and possesses exceptional resistance to stress-corrosion cracking in chloride-bearing solutions. Its high chromium and molybdenum content allows it to withstand both oxidizing and non-oxidizing acids and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides. It is very resistant to sulfide stress cracking and stress-corrosion cracking in sour oilfield environments.

Nistelle C-276 has been used in sour gas recovery and handling equipment, sulfuric acid environments (heat exchangers, filters and mixers), flue gas desulphurization equipments (scrubbers and ducting), pulp and paper production equipment (digesters and bleaching equipment) and in waste treatment facilities.

| SPECIFICATION | PRODUCT FORM |

| UNS N10276 | Powder |

| ASTM A494 CW12MW | Casting |

| UNS N30002 | Casting |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?