Delcrome 316 and 316L

Delcrome alloys are iron-based alloys with grades ranging from 316 and 410 stainless steels to much harder, wear-resistant, white cast irons. Delcrome alloy grades can be suitable for addressing general-purpose wear applications, with the harder grades typically used where abrasive wear is the primary concern.

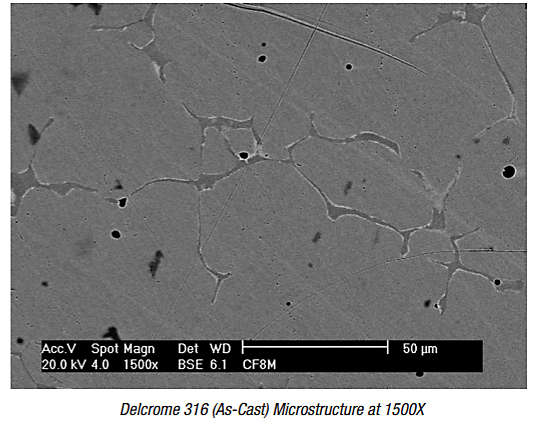

Delcrome 316 is an austenitic general-purpose stainless steel. It offers corrosion and oxidation resistance up to 750ºC (1380ºF). It is often used in component restoration and is easily machined. Delcrome 316L is used more often where susceptibility to corrosion is a concern, particularly if the method of application is welding.

Delcrome 316/316L can both be cast and are useful for material build-up and in PTA applications as a buttering layer. Typical applications include pump sleeves, tank linings, exhaust fans and blowers, compressor rods, plungers, hydraulic rams, paper mill rolls, pump impellers, cylinder bores, mixer blades, drive shafts and furnace equipment.

Available Product Forms

Delcrome 317/316L is available as powder, finished castings and additively manufactured components.