Tribaloy T-400 and T-400C

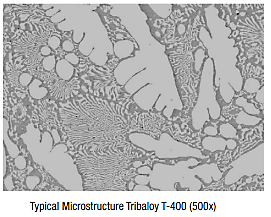

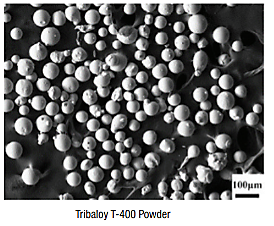

Tribaloy cobalt-based alloys consist of a hard, intermetallic (Laves) phase dispersed in a softer matrix of eutectic or solid solution. They exhibit outstanding resistance to wear and galling, high corrosion resistance and are particularly suitable where lubrication is a problem. Wear resistance of Tribaloy alloys is highly dependent on the volume percentage of the Laves phase.

Tribaloy T-400 combines excellent mechanical wear resistance with good corrosion resistance. T-400 contains hard intermetallic phases of Mo and Si which give the alloy excellent wear properties over a wide temperature range. T-400 exhibits outstanding resistance to galling. T-400C offers improved oxidation corrosion and high-temperature wear resistance over T-400 as well as improved thermal shock resistance.

T-400 and T-400C are known for their use in automotive turbocharger applications. Other areas of application are in situations where:

- Metal-to-metal wear exists

- Surfaces cannot be lubricated (e.g. high temperatures)

- Lubrication starvation exists

- Fluid lubricant is of low viscosity

- Both wear and corrosion are factors