Nominal Composition (Mass %) and Physical Properties

| Ni | Cr | Si | Fe | C | B | Hardness | Density (deposit) | Melting Range |

| Base | 7.5 | 3.5 | 2.5 | 0.3 | 2.0 | 35-45 HRC | 8.14 g/cm3 0.294 lb/in3 | 960-1107ºC 1760-2025ºF |

| Ni | Cr | Si | Fe | C | B | Hardness | Density (deposit) | Melting Range |

| Base | 7.5 | 3.5 | 2.5 | 0.3 | 2.0 | 35-45 HRC | 8.14 g/cm3 0.294 lb/in3 | 960-1107ºC 1760-2025ºF |

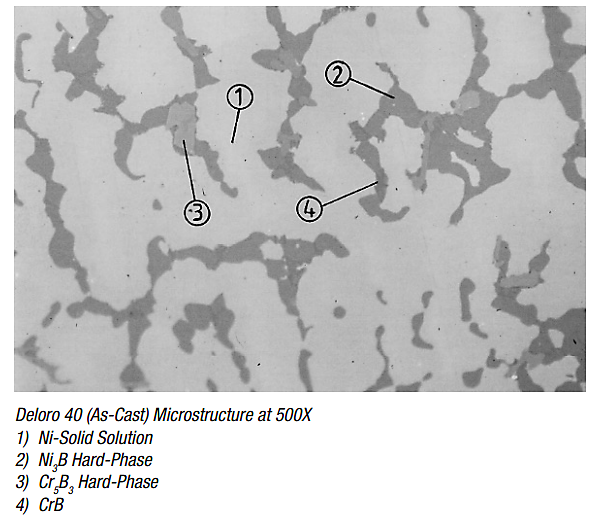

Deloro Alloys are nickel-based with additions of typically Cr, C, B, Fe and Si. They cover a very wide range of hardness, from soft, tough, build-up alloys that are easily machined to exceptionally hard, wear-resistant alloys. The high hardness comes from the very complex microstructure consisting of Ni-solid solution, Ni3B, Cr5B3, Cr2B, CrB hard phases and various Cr carbides. They can be selected for hardnesses of between 15 and 60 HRC and above depending on the application. Si and B make the alloys self fluxing and their low melting point makes powders ideal for spray/fuse or powder and rod/wire welding applications. They maintain their properties up to temperatures of about 315ºC (600ºF) and also offer good oxidation resistance.

Deloro 40 is a NiCrSiB alloy developed primarily for the surfacing of steels and is also available as a casting. The alloy contains complex carbides, borides and nitrides in a tough nickel matrix and provides protection from corrosion and both abrasive and sliding wear. Deloro 40 offers a good combination of impact resistance and wear resistance and should be considered where impact could be a factor with harder Deloro grades.

| SPECIFICATIONS | PRODUCT FORMS |

| AWS A5.21 ERNiCr-A | Rod |

| UNS N99644 | Rod, Powder |

Models

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Minimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?