Best in Class Hardfacing Technologies

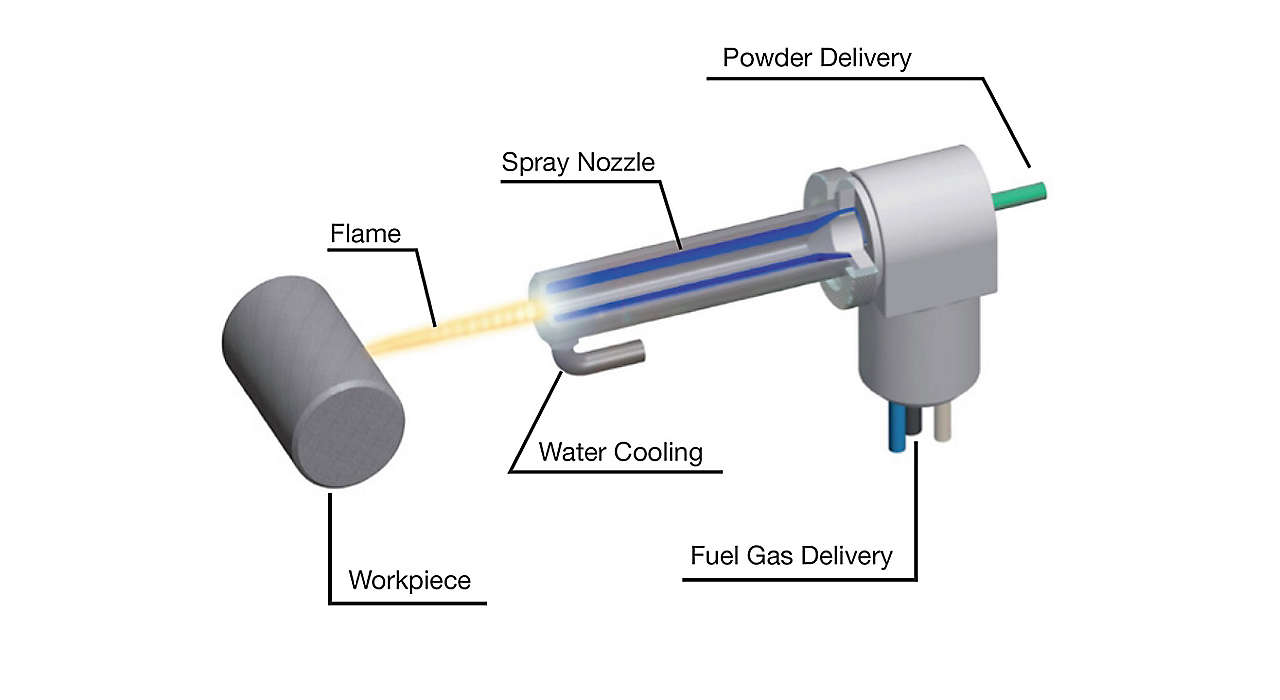

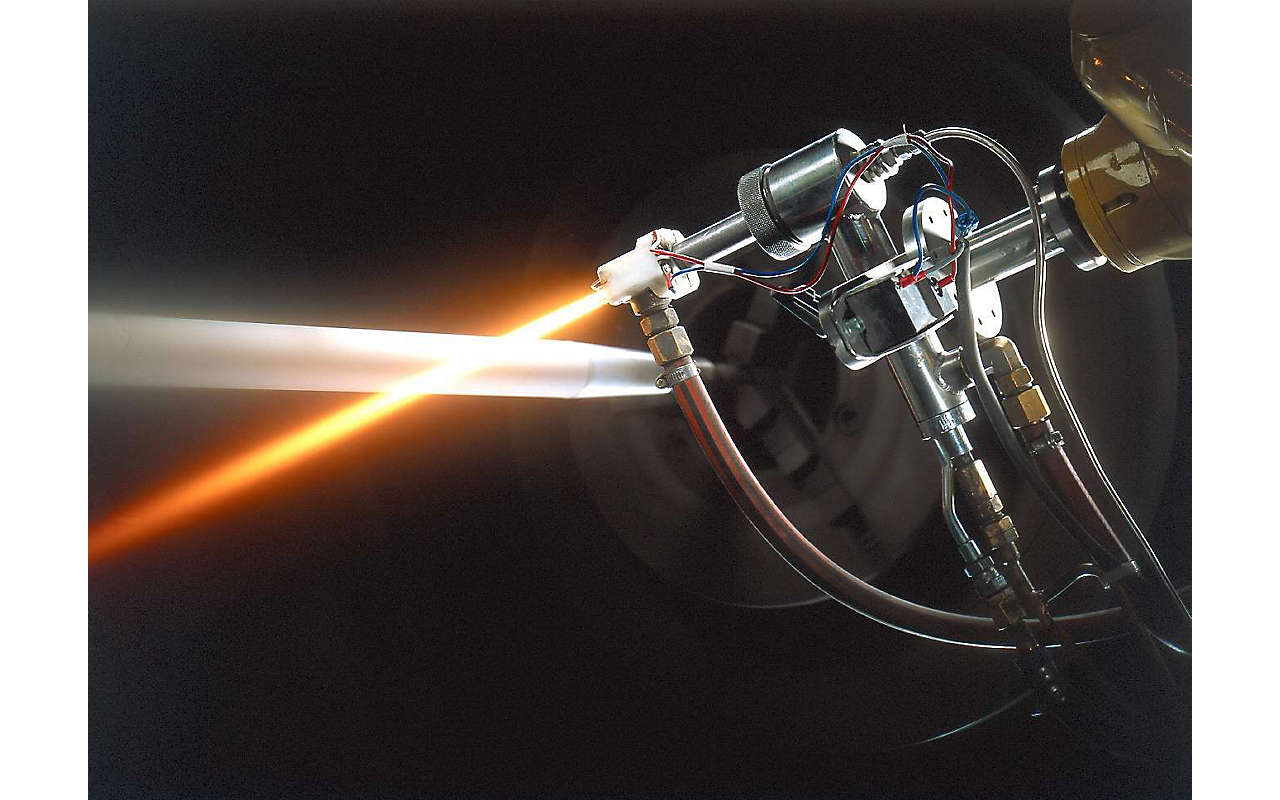

Kennametal Stellite™ specializes in high velocity oxygen fuel (HVOF) thermal spray systems which can apply high-quality and dense metallic and composite coatings onto various surfaces. Each Jet Kote HVOF system is designed with convenience and efficiency in mind, allowing operators to capture optimum workflow throughput without sacrificing product quality

Kennametal Stellite’s Jet Kote HVOF equipment is used in a range of industries, including aerospace, oil & gas, power generation, steel and general industry. This equipment enables these industries to leverage the exceptional properties of Stellite’s alloy families for wear and corrosion protection.