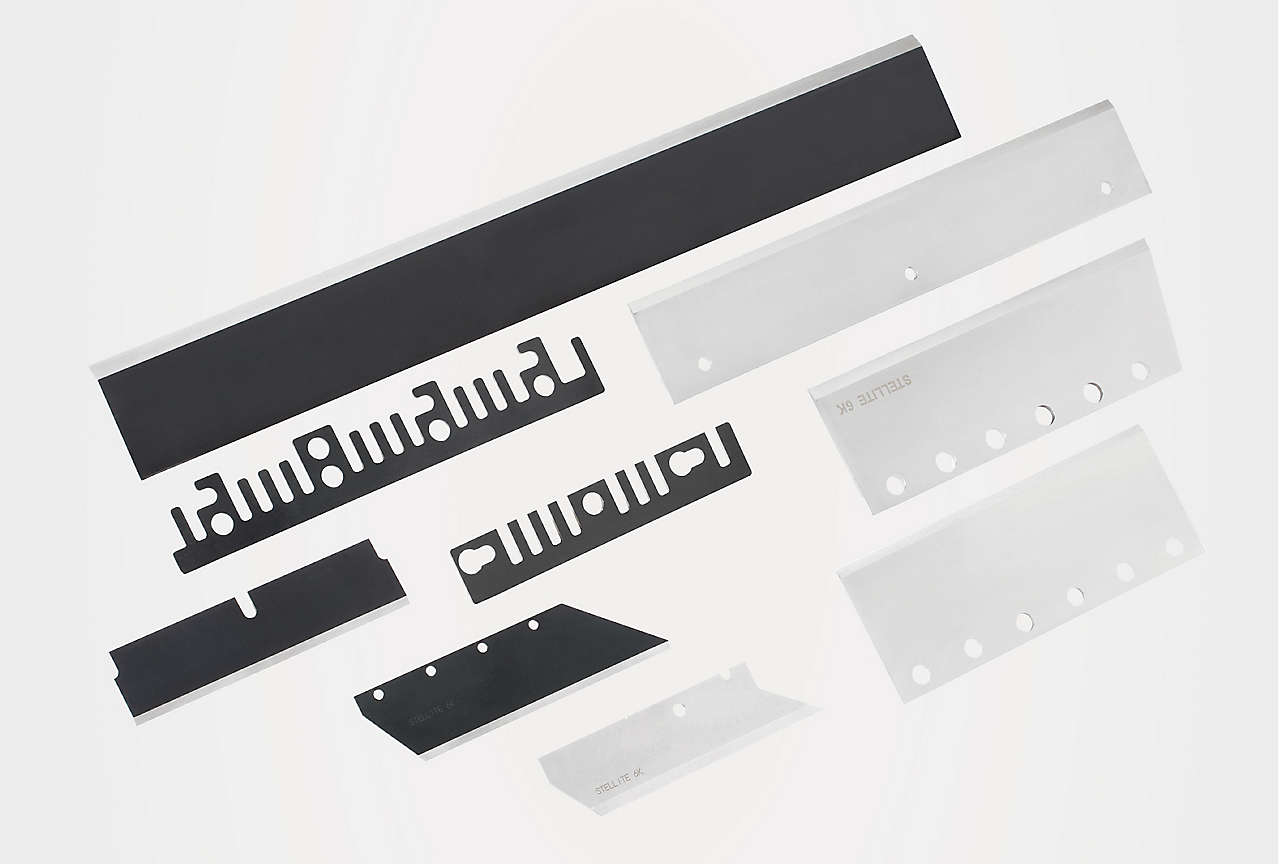

Combat Corrosion, High Temperatures, & Wear

For over 100 years, the Kennametal Stellite™ group has served those who have worked to transform our world: job shops, contract manufacturers, chemical processors, sawmills and a wide range of others who make a difference in our world. Our unique portfolio of custom manufactured components, stocked materials and hardfacing consumables serve a wide range of industries to mitigate the most extreme high temperature, wear and corrosive environments.