One Stop Design, Rapid Prototyping, and Production Partner

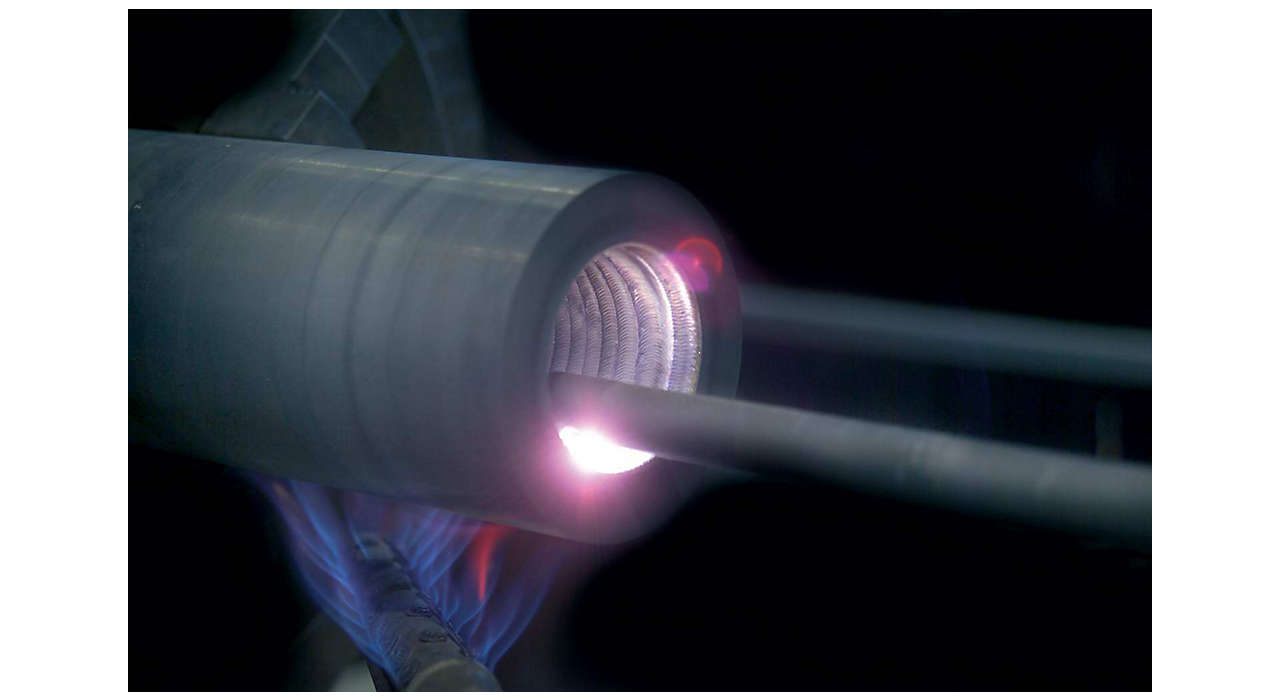

Since 1912, Kennametal Stellite has been a global leader in the manufacturing of cobalt and nickel-based components.

Today, Kennametal Stellite continues to be on the cutting edge of innovation with our rapid prototyping & 3D printing capabilities. Our engineers work in close collaboration so you can unlock full design freedom and bring products to market faster and more cost-effectively.

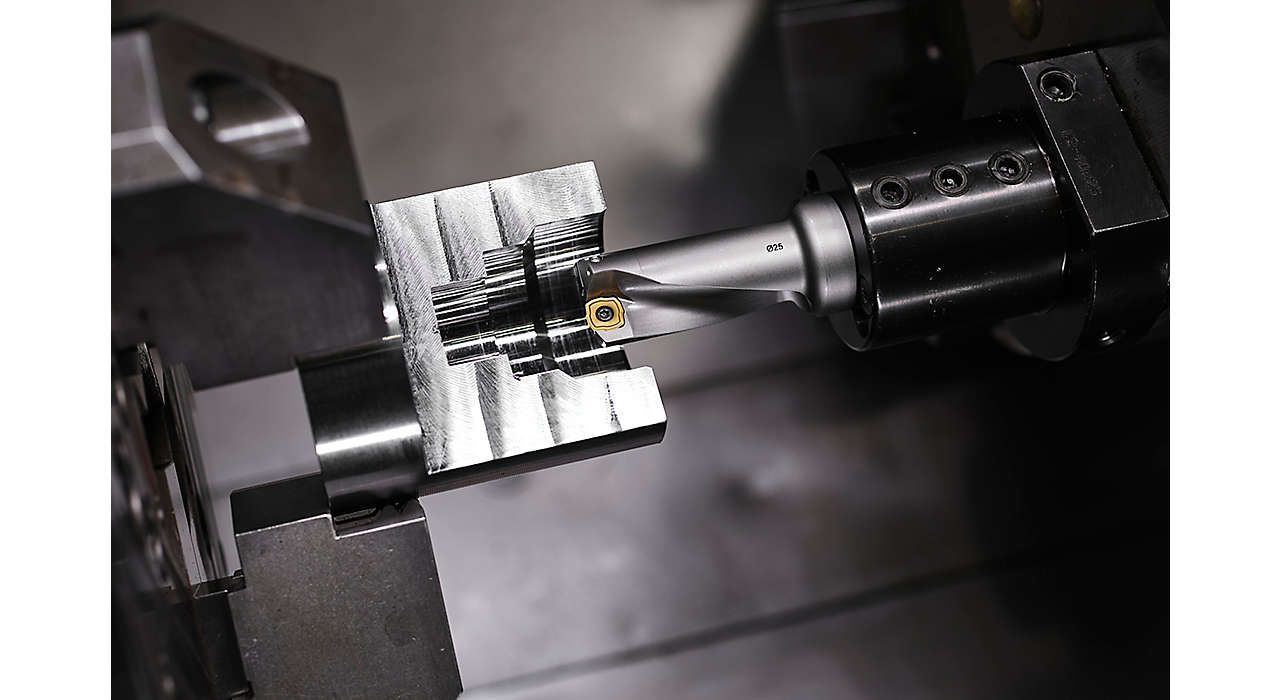

Within our fully equipped casting and machine shops, we deliver high-performance components to many industries including oil & gas, power generation, automotive, aerospace and defense, glass, pulp and paper, steel, galvanizing, wood cutting, food and other process industries.