Over 100 Years of Proven Performance in Welding & Hardfacing Consumables

With over 100 years of proven performance, Kennametal Stellite™ is known as the worldwide hardfacing solution provider for wear, heat and corrosion applications.

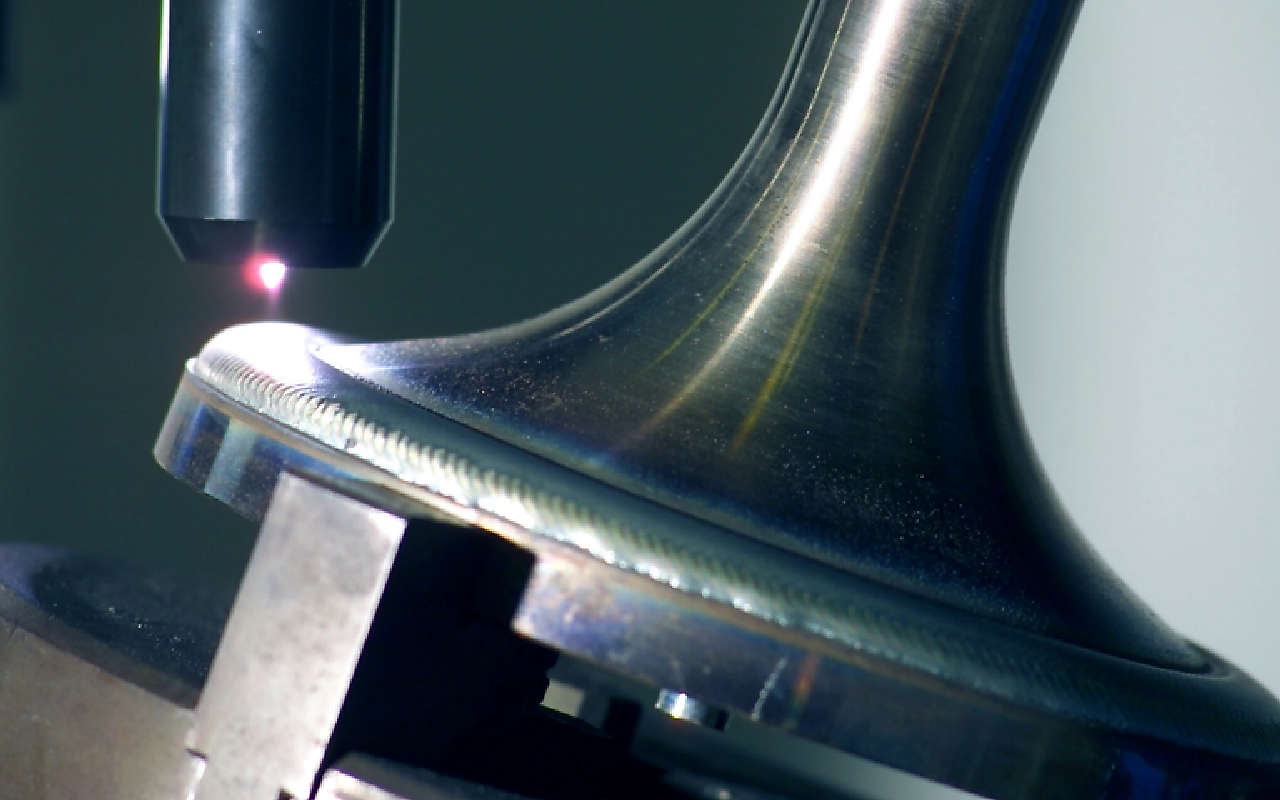

Kennametal Stellite’s thermal spray and hardfacing consumables are manufactured as cast rods, wire, powder and electrodes from our portfolio of over 300 unique alloys. Each of these alloys is backed by performance across major industries including aerospace, oil & gas, automotive, e-mobility, power generation, steel, timber, glass, dental and petrochemical processing.