Best in Class Hardfacing Technologies

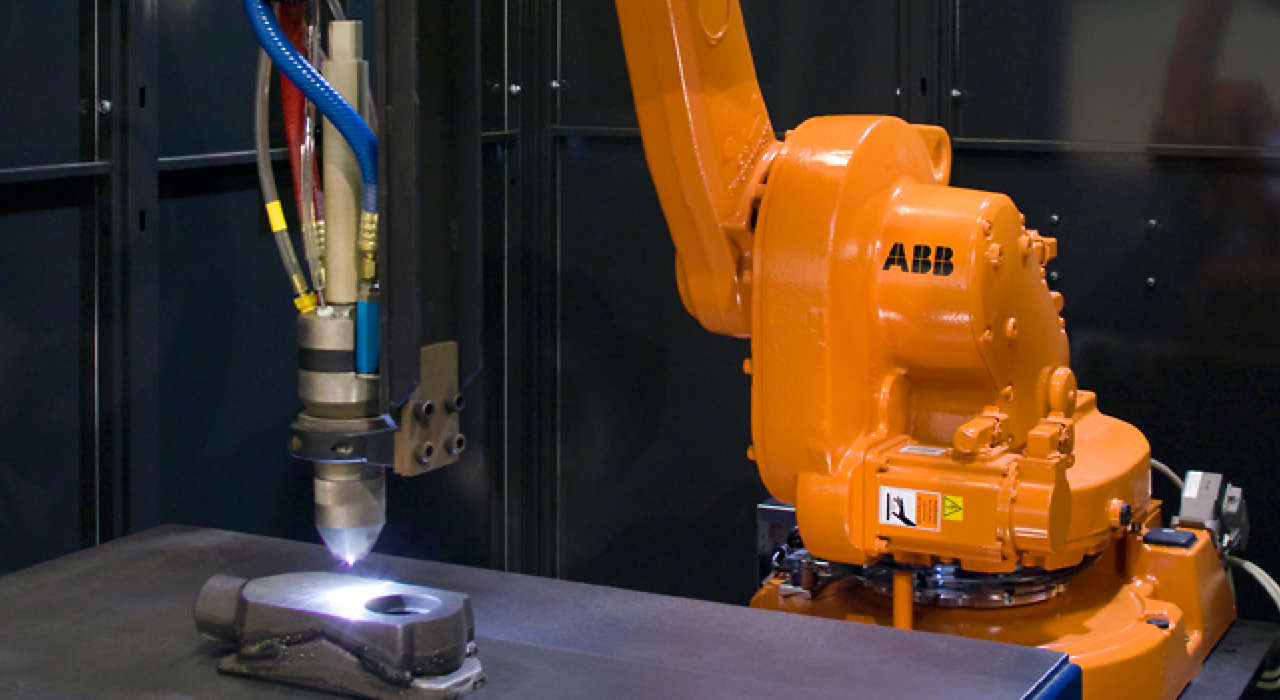

Kennametal Stellite is the leader in Plasma Transferred Arc (PTA) hardfacing which produces thick claddings from a high-energy plasma arc. By utilizing this cladding process Stellite’s customers optimize performance, reduce costs, improve reliability and extend the lifespan of critical assets and components.

Kennametal Stellite’s PTA equipment is used in a range of industries, including automotive, oil & gas, power generation, mining and general engineering. This equipment enables these industries to leverage the exceptional properties of Stellite’s alloy families for wear and corrosion protection.