Corrosion Resistance for Extreme Environments

Nistelle is a family of nickel-chromium base super alloys. The Nistelle family of alloys is designed for oxidation and corrosion resistance rather than wear resistance, particularly in aggressive chemical environments where their high chromium and molybdenum contents provide excellent pitting resistance. As a class, they are also generally resistant to high-temperature oxidation and hot gas corrosion.

Nistelle alloys are often used to mitigate corrosion in the most extreme environments. Kennametal Stellite’s two most popular alloys in this family, Nistelle 625 and Nistelle 718, have been widely used in a range of high-temperature aerospace, chemical process, oil & gas and power industry applications.

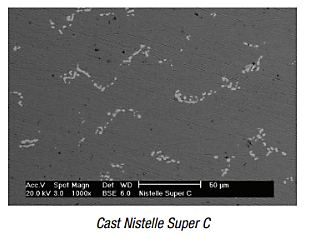

Kennametal Stellite’s Nistelle Super C is a proprietary developed nickel-base alloy designed for corrosion resistance and developed for the HVOF or PTA overlay processes. The corrosion resistance and surface finishing characteristics make Nistellle Super C an ideal alloy for claddings in printing, papermaking, oil refinery, and chemical processing industries.