The Right Material for Any Job

Kennametal Stellite’s broad portfolio of material solutions are used in nearly every industry where wear or corrosion occurs. The development of our family of alloys is attributed to several factors including manufacturing excellence, quality control, strong customer relationships and application expertise. Whatever the problem, there is a Kennametal Stellite product that will do the job well.

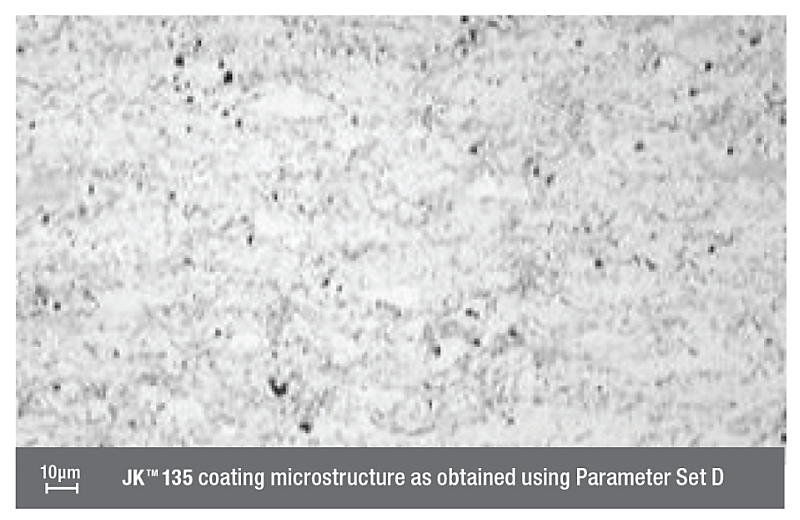

- Jet Kote powders feature a variety of alloys developed specifically for HVOF operations. These powders are designed to produce a well-bonded, high-density coating through most HVOF systems. The Jet Kote portfolio includes powders based on the Stellite family and an offering of unique carbide metal composite powders which provide excellent wear resistance.

- Stelcar and Super Stelcar are a group of exceptionally wear-resistant claddings developed for Plasma Transferred Arc (PTA) processes. Stelcar and Super Stelcar powders are typically a mixture of tungsten carbide in a nickel or cobalt matrix.

- Ultimet is a cobalt-based alloy with a unique combination of wear and corrosion resistance. The versatility of this alloy is enhanced by its superior (crack-free) weldability. Ultimet shows excellent performance characteristics in areas where galling, cavitation, erosion, or severe chemical attack is present.